ALN Security

Health,Safety and Risk Assessment Policy

At ALN Security, the health, safety, and well-being of our employees, clients, and stakeholders are our top priorities. We are committed to providing a safe and healthy working environment, minimizing risks, and ensuring compliance with all relevant health and safety regulations and standards.

Safety Policy Statements

ALN Security Services Ltd, referred to as ‘The Firm,’ has a law of protecting the health, safety, and welfare of its employees, as well as other people who may be affected by their work. In line with the specifications of the Health and Safety at Work Act, the Management of Health and Safety at Work Regulations, and other applicable legislation, the company will conduct risk assessments and implement commitments that, to the greatest extent possible, ensure;

- workplaces are kept in a safe condition;

- working environments are safe and free of ards;

- work equipment and systems are safe and free of hazards;

- suitable and sufficient resources are available;

- documentation, guidance, mentoring, and supervision are supplied to ensure the safety and wellbeing of its employees and those who may be affected by their work activities.

The General Manager is wholly accountable for the firm’s health and safety. He will ensure that adequate resources are available to achieve the policy’s objectives and will supervise its effectiveness. Managers/Line Managers and Supervisors are qualified to carry out the arrangements outlined in this policy in relation to the areas and activities under their supervision. The Policy will be reviewed and updated on an annual basis to reflect changes in operations and applicable legislation.

Responsibilities for Health & Safety

Managing Director

Maintaining a health and safety policy that satisfies the criteria of the Firm Safety Policy, making resources available for policy implementation in all aspects of business activity, Monitoring compliance to the safety program all through the company.

Operations Manager

- Guaranteeing that fire hazard analyses are completed; Making sure emergency arrangements are retained and actually practiced as appropriate.

- Scrutinizing accident investigation/incident reports and reporting accidents via the correct channels.

- Monitoring the progress of risk assessment initiatives during monthly business review meetings.

- Ensuring that employees are competent and adequately trained to discharge their defined safety responsibilities;

- Ensuring employees under their control discharge their defined safety responsibilities.

- Ensuring that they, and all employees under their direction, adhere to the safety policy and procedures.

- Monitoring the implementation of the policy at their location/place of work by undertaking annual safety reviews.

- Reporting to the Managing Director, any areas where the effectiveness of the safety policy and procedures could be improved.

Contract Managers

- Pre-contract site health, safety, and welfare assessments

- ensuring that assignment instructions define risk assessments, welfare arrangements, and emergency procedures

- Providing employees with the information, training, and supervision they require to work safely

- Conducting site inspections to ensure that assignment instructions are followed;

- Consultation with Security Officers on safety issues

- Conducting accident investigations in all incidents involving serious injury;

- Meeting with the client’s site representative on a monthly basis to resolve any safety issues

- ensuring that they, as well as all employees under their supervision, follow the safety policy and procedures and

- Any areas where the effectiveness of the safety policy and procedures could be improved should be reported to the Operations Manager.

ALN Security Services Ltd Employees

Cooperating in health and safety inspections, risk assessments, and accident investigations as needed; Attending training courses as needed; Following the laid down safety procedures; Undertaking their work in a safe manner in accordance with instructions and training provided; and reporting any unsafe occurrences to their Contract/Line Manager as appropriate.

Accidents

Summary Requisite

All workplace accidents must be recorded in an approved accident book and investigated to determine the actions required to prevent a recurrence. Specific injuries, diseases, and dangerous events must be reported to the appropriate enforcing authority through ALN Security Services Ltd.

Company Procedure

Recording Incidents

In the event of a workplace accident, all ALN employees should request guidance in first aider/appointed person and record the incident in the accident book. Security Officers must follow company procedures and adhere to the client’s arrangements for accident recording and investigation in order for the accident to be recorded in the ALN Accident Book. Accident reports that have been finished should indeed be excluded from the Incident Report and filed confidentiality agreement.

Accident and Incident Report

Accident and critical incident reports should then be forwarded to the appropriate Manager, who should document the findings of the research as well as the steps taken to prevent a recurrence. The structure should indeed have been sent to the Operations Manager/Head of Department, who might sign off on it if the investigation is concluded or if further action is required. Managers must ensure that reports for all incidents recorded in the dangerous occurrences are obtained on a routine basis.

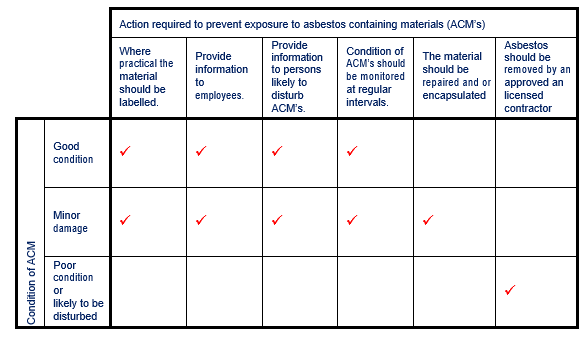

Asbestos

Requirements in Brief

Employers are required to conduct workplace surveys to determine the presence of asbestos-containing materials. If asbestos-containing materials are discovered, the employer must conduct an assessment that takes into account the type of asbestos, its condition, and the likelihood of disturbance. Based on the results of this assessment, the employer should decide whether the asbestos should be removed or managed to prevent fibre release.

Firm way of handling

- Managers are responsible for ensuring that Type 2 asbestos surveys are performed on all materials suspected of containing asbestos. Type 2 assessments include the analysis of any suspected asbestos-containing materials to determine whether the materials in question contain asbestos and, if so, what type of asbestos they contain.

- Managers are responsible for keeping track of the type and location of suspected and confirmed asbestos-containing materials (ACM) in their areas of control. Any materials that cannot be positively identified as asbestos-free should be treated as asbestos-containing.

- Managers are responsible for assessing the risks of any potential and confirmed asbestos-containing materials and implementing appropriate risk control measures in accordance with the guidance in the following chart.

- If presumed asbestos-containing components that are in poor condition or are likely to be disturbed are defined, relatively brief risk control measures must be implemented to avoid contamination till the resources can be removed.

- No asbestos-containing materials should be disturbed by employees. Any destruction to known asbestos-containing materials or the discovery of potentially asbestos-containing materials should be reported to their Manager.

Buildings, Services & Equipment

Workplaces and equipment must be fit for their intended purpose and kept in a safe condition. Work equipment should only be used by competent people who follow the manufacturer’s instructions. Only qualified individuals should perform maintenance.

Managers and purchasing personnel are responsible for ensuring that buildings and work equipment are fit for purpose. To ensure compliance with applicable product safety standards, all new work equipment should be CE marked. Managers are responsible for ensuring the safety of buildings, services, and workplace equipment. All work equipment should be used in accordance with the instructions provided by the manufacturer. Only properly trained and authorised employees should operate hazardous work equipment. Employees are responsible for performing pre-use equipment inspections. Any flaws discovered in the building, associated services, or equipment should be reported to the Operations Manager / Head of Department. Staff must not attempt to repair or use defective services or products.

Managers should also check with their clients to determine who is responsible for the maintenance and testing of the following equipment and services. These pieces of equipment include:

- lifts

- lifting apparatus

- gas-powered appliances

- electrical devices

- electrical connections

- fire detection systems

- extinguishers for fires

- systems and pressure vessels

- air conditioning units

- bottled water dispensers

Contract Managers should ensure that clients have adequate maintenance arrangements in place when such equipment is provided. Maintenance schedules and record sheets should be used to ensure that necessary maintenance is performed.

Consultation

Managers are in charge of consulting with their employees on a daily basis. On contract sites, health and safety concerns can be raised with the Client or the Contract Manager directly. The assignment instructions should include the client’s point of contact for health and safety.

If an employee is dissatisfied with their manager’s or client representative’s response to a health and safety issue, they should raise it with their Contract/Line manager. If necessary, the Contract/Line manager will seek additional information from the Company’s Health and Safety advisor.

Contract Managers should initial and date the entry during the subsequent site visit to verify that it has been affirmed and is being addressed.

Record Keeping Requirement

- Security Officers should record any safety concerns or recommendations for improvements in the Daily Occurrence Book (DOB)

- Contract Managers should initial and date the entry during the subsequent site visit to confirm that it has been acknowledged and is being dealt with.

Contractors

Requirement Summary

Employers are responsible for ensuring their employees’ health and safety at work, which includes protecting employees from hazards associated with contractors’ activities. Employers are responsible for ensuring the safety of others who may be harmed by their activities, including contractors, who should be made aware of any hazards on the premises before beginning work.

Company Policy

Contractors are responsible for all activities. Contract/line managers are responsible for ensuring that all contractors engaged to work on ALN premises are competent, for example, electricians are NICEIC members, gas maintenance contractors are CORGI members, and builders are members of a skills certification scheme.

Major Projects

The Construction, Design, and Management Regulations may apply if one or more of the following criteria apply to works to be performed by a contractor; A duration of more than 30 days; A duration of more than 500 person days; Five or more people on site at any given time; and Dismantling. ALN Security Services Ltd has specific duties that must be fulfilled in such cases, and Contract/Line managers should contact the Operations Manager for further guidance.

Display Screen Equipment

Requirement Summary

Employers are responsible for ensuring that significant computer users receive information about the proper use of display screen equipment and that workstation assessments are performed. Significant users are also entitled to employer-paid eye exams and corrective spectacles if the eye exam reveals that a different prescription is required solely for computer use. Those who use their computers continuously for an hour or more per day are heavy users of display screen equipment.

Company Procedure

Managers should identify all significant users and provide them with the HSE guidance ‘Working with VDUs’ as well as self-assessment questionnaires. Significant computer equipment users must read the guidance, complete the assessment questionnaire, and return it to their manager. The Manager should ensure that significant users return questionnaires, as well as review completed questionnaires and address any risks identified.

Employees who are required to use display screen equipment for extended periods of time are entitled to company-paid eye exams. The purpose of the eye test is to see if the employee can focus clearly on the image on the display screen, using their normal spectacles as needed.

Enforcement Officers

Requirement Summary

Environmental Health Officers have the authority to monitor and enforce safety legislation in workplaces such as offices, restaurants, distribution centres, and retail establishments. Health and Safety Executive Inspectors are in charge of overseeing and enforcing safety regulations in factories, laboratories, refineries, chemical plants, and health care facilities. Enforcement Officers have broad powers, which are outlined in their warrants. Enforcement officers are required to produce their warrants upon request; without them, they have no powers of entry or enforcement. Officers of the law have the legal authority to:

- Enter and inspect premises with the assistance of police officers if necessary;

- Require that plant and equipment not be disturbed following an incident;

- Take measurements, photographs, and samples of suspect substances;

- Require tests on suspect plant or substances;

- Require plant dismantling;

- Require those with possible knowledge relevant to an investigation to provide it either verbally or in writing;

Company Policy

Everyone should cooperate fully with Enforcement Officers, and they should be accompanied by the most senior member of staff available during their inspections. Copies of inspection reports should be sent to the Company Health and Safety Advisor. Any contact with law enforcement should also be reported to the Company Health and Safety Advisor.

Fire

Summary Requirement

Employers are required to assess the fire risks on their premises to ensure that the risk of fire is minimized and that appropriate arrangements are provided for the safe evacuation of employees in the event of a fire occurring.

Company Procedure

Risk Assessment

Contract/Line managers are responsible for ensuring a fire risk assessment is carried out for all premises under their control.

Fire risk assessments should be undertaken to ensure the effectiveness of the fire safety arrangements. The fire risk assessment should define the arrangements and requirements for ensuring adequate provision of fire prevention and detection systems, fire fighting equipment, provision of training and information, and the maintenance of installations and equipment provided for the purposes of detection and firefighting. Particular consideration should also be given to issues such as hazardous or dangerous substances and young persons. The arrangements for fire safety on contract sites are reviewed by contract managers during the site risk assessment and specified in the assignment instructions.

The significant findings of the fire risk assessment, along with any specific fire training deemed necessary, should be provided to employees, and the provision of such information and training should be recorded. Records should be signed by the employees to confirm they have received and understood the information and training provided.

Risk assessments should be reviewed prior to any significant changes to ensure such changes will not increase the risks to an unacceptable level. If there are no significant changes, the risk assessment should still be reviewed annually to ensure it remains suitable and relevant and the control measures are still the most effective way to manage the risks. Fire Authorities shall no longer issue or enforce Fire Certificates but will expect to see risk assessments when carrying out site visits.

Fire evacuation procedure

Formal fire evacuation procedures must be posted at all facilities where ALN personnel reside. The procedure should detail the means by which the alarm is triggered, the means of evacuation from the building, and the meeting place designated for firefighting.

If a fire is found, personnel will need to sound an alarm and evacuate from the danger zone. The fire brigade should be called from a safe position. Upon hearing the alarm, personnel should turn off the equipment they are using and evacuate the building as soon as possible.

Do not use the elevator during fire evacuation. No one should re-enter the building until instructed by the customer or department manager.

Fire extinguisher

The fire extinguisher provided must be suitable for the nature of the risk.

- A fire extinguisher (red) should be provided for common fires such as paper, wood and cloth.

- For electrical fires, you need to have a carbon dioxide (black) or dry powder (blue) fire extinguisher.

- For flammable liquid fires in the kitchen area, a foam fire extinguisher (cream) or fire blanket must be provided.

Note: All new fire extinguishers are red. Different types of fire extinguishers are identified by labels and small color-coded panels. Only those who are trained in the use of the fire extinguisher should attempt to extinguish the fire only if it is safe. All firefighting equipment should be inspected and serviced annually by an authorized contractor.

Record retention requirements

- A copy of the fire risk assessment must be retained in the safety management file.

- Maintenance of firefighting equipment should be recorded in the maintenance log of the safety management file.

- Maintenance of fire protection systems such as alarms, emergency lights, call points, sprinklers, etc. should be recorded in the maintenance log of the safety management file.

- Fire alarm tests and fire drills should be recorded in the fire log of the safety management file.

- Information and training provided to employees should be recorded in the safety management file information and training logs.

Note: Existing fire certificates and approved changes to them should be archived.

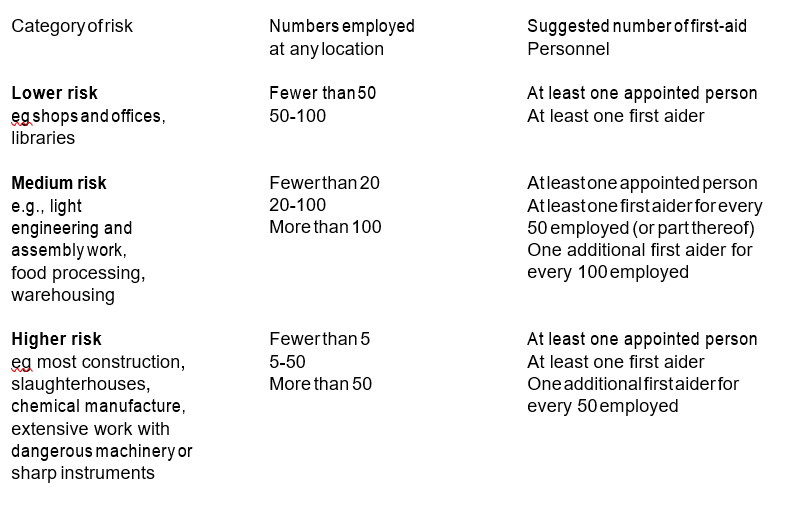

First Aid

Summary requirements

Employers are obliged to provide appropriate first aid, taking into account the risks associated with the business, the number of employees and the proximity of emergency services.

Company procedures

Precautions regarding first aid

First aid supplies must be provided and maintained on all workstations where ALN employees are located. In offices with more than 50 employees, the first responder needs to be trained and ordered. In offices with less than 50 employees, designated individuals should be held accountable and first aid supplies should be available for first aid.

We encourage all assigned people to participate in emergency response training. The designated person must not provide first aid unless trained. Planned absences of officers and first aid must be coordinated to ensure proper care. First responder or nominee names and contact details must be posted on the bulletin board. First aid and equipment provision arrangements at the contract site are considered by the contract manager during the site’s risk assessment and the requirements are specified in the work order.

Treatment Records

Records of all first aid treatment should be maintained and should include the name of the injured party, date, time and details of the incident, injury and treatment. These details should be recorded in Part 1 of the company’s accident investigation report form – see earlier section regarding accidents.

Recordkeeping Requirements

- The name and contact information of the first responder must be recorded and displayed on the bulletin board.

- Training for persons designated as first responders should be recorded in the safety management file information and training logs.

- First responders are required to record all treatments listed in the accident investigation report. See the previous section on accidents.

Hazardous Substances

Summary requirements

Employers should avoid the use of dangerous goods as much as possible. If the use of toxic substances is unavoidable, employers need to make an assessment to ensure that controls are in place to keep workers’ exposure at safe levels.

Company procedures

The administrator is responsible for ensuring that all dangerous goods used by employees or sites under their control are identified and recorded in the register. The administrator is also responsible for ensuring that the COSHH register is maintained, safety data sheets are obtained from the manufacturer / supplier, and a regional COSHH assessment is performed for all dangerous goods listed in the register. When using substances listed in the

COSHH Registry, the information contained in the Safety Data Sheet must be used when conducting an exposure assessment of workers. Assistance in conducting COSHH assessments is available through Occupational Health and Safety Advisors. The supervisor is responsible for ensuring that the precautions deemed necessary by the COSHH assessment are in the attention of the employee and are always adhered to.

Record keeping requirements

- All dangerous goods used must be recorded in the COSHH register of the safety management file.

- Safety data sheets for all substances identified in the COSHH register must be obtained and stored in a safety management file.

- A copy of the COSHH rating should be kept in a safety management file.

- Information provided to employees regarding the safe use of dangerous goods should be recorded in the information in the safety management file and in the training log.

Information

Summary requirements

The employer must inform the worker about the health and safety requirements and health and safety precautions that apply in the workplace.

Company procedures

The following information should be posted on all ALN facilities.

- Health and safety policy statement.

- Professional compensation insurance policy.

- Evacuation procedures in case of fire. When

- First aid precautions.

We encourage all employees to provide a summary version of their security policy and a manual containing key findings of a general risk assessment applicable to their work. The instruction for use at the contracted location must include location-specific assessments and contact details for the client’s occupational safety officer. The contract site should also provide the following information:

- Site-specific fire evacuation procedures.

- Arrange for site-specific first aid.

- Site-specific welfare regulations.

- Site-specific accident investigation procedures. When

- Report on the Industrial Safety and Health Act.

Record-keeping requirements

- Issuance of employee health and safety manuals must be recorded in the information in the safety management file and training records.

Manual Handling

Summary Requirement

Employers have to keep away from the guide managing of hundreds in which feasible. Where guide managing can’t be averted exams of the venture have to be undertaken to make sure suitable precautions had been taken to save you injury.

Company Procedure

Managers are accountable for making sure that, in which feasible, the want to manually deal with heavy hundreds on a normal foundation is averted. Where it isn’t always feasible to keep away from guide managing of heavy hundreds on a normal foundation Managers are accountable for making sure guide managing exams are undertaken. Assistance in project guide managing exams is to be had thru the Company Health and Safety Advisor.

Managers are accountable for making sure that any precautions deemed important with the aid of using the guide managing evaluation are implemented, and people required to manually deal with heavy hundreds are furnished with suitable protection schooling.

Regardless of the burden, all guide managing sports have the ability to purpose harm. The following technique have to be found while lifting any load:

- Plan the carry earlier than you start, how are you going to grip it, in which have you bought to take it, what direction will you take, is the direction freed from obstructions, in which and how are you going to positioned it down;

- Stand near the burden, vicinity the toes aside with the main leg ahead for balance;

- When lifting gadgets from underneath waist top bend the legs, now no longer the back;

- Get a company grip, hold your fingers withinside the boundary fashioned with the aid of using the legs;

- Evaluate the burden of the burden and the middle of gravity;

- Only maintain with the carry in case you are certain that you could carry, deliver and decrease the burden appropriately;

- Lift slowly the usage of your leg muscular tissues to face and hold the burden near your frame;

- Do now no longer jerk or twist the frame at the same time as lifting, carrying, or reducing the burden;

- Put the burden down slowly, the usage of your leg muscular tissues if the burden is to be lowered; and

- Adjust the burden handiest after you’ve got positioned it down.

Seek help if a load is just too heavy or cumbersome to boost appropriately for your personal – do now no longer try to carry a load for your personal in case you experience it isn’t always inside your functionality to achieve this appropriately.

Record-Keeping Requirements

- Completed guide managing exams have to be saved withinside the protection control file.

- Manual managing schooling furnished to personnel have to be recorded withinside the data and schooling report withinside the protection control file.

Risk Assessment –Office Premises Only

Summary Requirement

The Management of Health and Safety at Work Regulations require all employers to assess risks to staff and others arising from their undertakings. The assessment should:

- Identify the hazards present;

- Identify persons at risk;

- Identify any groups of persons at special risk (including pregnant and nursing mothers and young persons); and

- Evaluate the risk, taking account of existing control measures.

The purpose of the assessment is to identify the measures that should be taken to ensure the safety of those at risk and confirm compliance with applicable statutory requirements. It should ignore trivial risks and should not be obscured by excess information. The significant findings of assessments should be recorded and provided to appropriate employees.

Company Procedure

Generic risk assessments have been undertaken of the foreseeable hazards associated with office activities and summaries of the assessments are included in the handbook issued to office based employees. The generic assessments for office work cover:

- Slips trips and falls;

- Use of electrical appliances;

- Access to high level shelving;

- Occupational driving;

- Use of filing cabinets; and

- Use of photocopiers.

Managers / Line Managers are responsible for ensuring that the generic risk assessments are amended to make them effective in identifying and reducing the risks associated with the areas and activities under their control and for undertaking site-specific assessments of any hazards not covered by the generic risk assessments.

Managers are responsible for ensuring that the safe systems of work defined in risk assessments are brought to the attention of all office-based employees and for monitoring employees to ensure they adhere to the requirements on a day-to-day basis.

Risk Assessments Specific Hazards

Specific regulations and guidance have been produced by the HSC which require detailed assessments of the following:

- Substances Hazardous to Health;

- Manual Handling Operations;

- Display Screen Equipment; and

- Fire Safety in Buildings.

Managers are responsible for assessing the hazards associated with the areas or activities under their control and where a significant risk from any of the above hazards is identified reference should be made to the specific arrangements detailed in the safety management file.

Risk assessment – Customer Premises

Summary requirements

Occupational health and safety regulations require all employers to assess the risks to employees and others arising from their work. The evaluation should be as follows.

- Identify existing hazards.

- Identify vulnerable people.

- Identify vulnerable groups, including pregnant and lactating mothers and adolescents. When

- Assess risk by considering existing controls. The purpose of the

assessment is to identify the steps that should be taken to ensure the safety of those at risk and to ensure compliance with applicable legal requirements. Ignore the insignificant risks and don’t hide them with extra information. The main findings of the assessment should be recorded.

Therefore, ALN is responsible for assessing the risks associated with the services provided by security personnel on customer sites. Customers must provide ALN with an assessment of the risks arising from business activities that may affect the ALN Security Officer while working in the field.

Health, Safety and Welfare Regulations require employers to provide adequate welfare facilities while employee’s work. These facilities include:

- Sanitary facilities.

- Bathroom.

- A healthy drinking water supply.

- Clothing accommodation.

- Equipment for putting on and taking off special clothing.

- A facility for preparing / receiving hot food and drinks. When

- Facilities for breaks and meals.

To ensure that employees meet these requirements where they work at the customer’s site, Occupational Health and Safety Management Regulations ensure that employers meet health and safety requirements and provide appropriate social facilities. We seek to coordinate and coordinate health and safety activities.

Company procedures

ALN Security Services has a legal responsibility to ensure the health and safety of all employees, regardless of where they are hired. This responsibility is to protect the employee from the risks arising from the activities in which the employee is employed, and to protect the employee from the risks arising from the activities performed by the client at the contract construction site. Includes ensuring that action is taken. You also have a legal responsibility to ensure that business risks do not harm ALN employees.

A general risk assessment of the foreseeable risks associated with security activities was carried out. This evaluation is used to develop a general safety work system that is incorporated in the health and safety manual issued to safety personnel. Evaluation and safe working systems include:

- Oral and / or physical abuse.

- Driving a company car.

- Work near a moving vehicle.

- Use of electronic devices.

- Handling suspicious packages. When

- Slip, trip, fall.

The Contract Manager is responsible for conducting site-specific assessments to ensure that the precautions necessary for the health, safety and well-being of safety personnel are in place at the Contract Site.

Contract managers should refer to general security risk assessments when conducting risk assessments and obtain relevant information from clients regarding critical risks, emergency preparedness, and on-site welfare facilities.

The contract manager will work with the client to ensure that short-term measures are taken to reduce all risks identified in the assessment to acceptable levels before safety personnel are placed on the contract site. need to do it.

A copy of the completed health, safety and welfare assessment should be provided to the client and attached to the on-site work order. Additional copies should be kept in the location file of the ALN Security Operations Office.

The Contract Manager is responsible for monitoring compliance with order instructions during site visits and, depending on the level of risk, raising issues related to the dangers of onsite business activities with clients at or before monthly meetings. I have.

Operations Administrators are responsible for reviewing the progress of site-specific assessments and implementing the resulting recommendations with Contract Administrators during monthly business meetings.

Risk Assessment Specific Hazard

HSC has established specific regulations and guidelines that require the following detailed assessments:

- Substances that are harmful to health.

- Manual processing operation.

- Screen equipment. When

- Building fire protection. If the

assessment identifies a significant risk from any of the above hazards, you should refer to the specific precautions contained in the safety management file.

Recordkeeping Requirements

- Site-specific safety and welfare assessments of contract sites should be included in appropriate customer files and work instructions.

Smoking

Summary Requirement

Smoking is prohibited in all enclosed workplaces and company vehicles in the United Kingdom.

Company Procedure

In accordance with current legal requirements smoking is prohibited in all enclosed ALN premises or vehicle. This prohibition applies at all times, including outside normal working hours. Smokers may smoke outside the premises at times, and in places, previously agreed with their line manager. All visitors, temporary staff, contractors and customers will be expected to abide by the terms of the smoking policy. Appropriate signs will be displayed at all entrances to premises and employees should tactfully remind visitors of the policy, if necessary. Security Officers should observe the clients’ local arrangements for smoking whilst on site.

Training

Summary Requirement

Employers must provide their employees with information and training to enable them to work safely and discharge their defined safety responsibilities.

Company Procedure

All new starters, promoted, and transferred employees are provided with information and training appropriate to their responsibilities as defined in the ALN safety policy and the risks to which they may be exposed during their work.

Security Officers are provided with a two-day onsite induction and training in accordance with the British Security Industry Association requirements. This training covers the ALN health and safety policy, generic risk assessments, and arrangements for providing site-specific health and safety information.

All officers are provided with local induction training by the Managers / Line Managers. This training will cover ALN’s safety policies, community emergency preparedness, and risk assessments that can be applied to the workplace.

In addition, the following training is provided to fulfil specific safety responsibilities:

- All site administrators, supervisors, and executives receive module awareness training and evaluation. This training covers key criminal and civil law requirements for health and safety, the operation and implementation of ALN safety policies.

- Contract managers receive general risk assessment training. This training provides managers with the skills needed to identify risks, quantify risk, and implement the management actions needed to reduce risk to acceptable levels. The

training courses are conducted at appropriate intervals throughout the year and are always conducted after the installation of new equipment or major changes to existing work systems. All information and training should be recorded to ensure that it has been provided and understood. In addition, all officers receive “site-specific training” on all matters related to the assigned site.

Record retention requirements

- Deployment training for all employees must be recorded using a copy of the deployment training checklist. This checklist should be kept in the employee’s personnel file.

- Safety personnel training should also be included in general safety personnel training and performance records.